I don't know where to start or how to start this review, especially after receiving the biggest shock of my life – a positive one that is. I was left speechless after Beirut's McDonald’s team took me on a tour behind the action that goes on behind the counters. What we believe is just a simple burger; actually takes much more effort than we know…

A while back I talked about all the negative things I, and many others around me, have been experiencing at McDonald’s Beirut. I received a call from the management to come and check on their progress and keeping up with their international counterparts. They took me on a complete tour behind the scenes proving that they have worked on every negative point mentioned in my previous review. And believe me, they have succeeded. I am very happy to witness that. At 10am, I had an appointment with Shady, Samer and William from McDonald's who took me on a detailed tour around the kitchens. I got the chance, a few do, to learn about the process behind creating their signature food items.

You, like me, may have asked yourself: “After all, how complicated is it to make a simple burger...?" Well, it is hard. I was proven wrong. McDonald's works on a "we have nothing to hide" policy. They invite anyone to visit their kitchens and discover the complex process behind creating their well renowned menu. What you will see below is an exclusive and detailed behind-the-scenes review of McDonald's Beirut, thoroughly following the detailed international guidelines, to offer their customers the ultimate quality and service that should be replicated all around the world. The pictures taken are a premiere. The story at McDonald’s begins at the back end area with a door that can only be opened from the inside to receive daily produces. Before the truck is unloaded, a food safety officer checks the food’s temperature; Frozen goods should be stored at -18 degrees Celsius and refrigerated ones at +2 degrees Celsius. If by any chance this requirement is breached, the truck is sent back and the products will be destroyed. All ingredients used at McDoanld’s are imported except for the vegetables, which are locally produced in the Bekaa Valley following meticulous auditing from McDonald's international.

The back kitchen sections:

- The hand washing area

- The cleaning and decontamination hub

- The vegetables preparation and cutting unit

- The multiplex soft drink mini factory

- The main fridge followed by the main freezer

- The different on-hand small freezers

- The main hamburger preparation table

- The meat grilling furnaces

- The meat heating towers

- The French fries special dispensers

- The French fries frying unit

- The compartment frying sink

Behind the main counter is an area that looks like a hospital:

- Everything is cleaned and cleaned again every hour

- Every section has its special specific antibacterial product

- Everything is timed with an alarm to remind the staff to stay clean and refresh their units

- The cleaning process of all the machinery and equipment is strict: Soaping, Rinsing, Sanitizing for 10-15 minutes, and then Drying

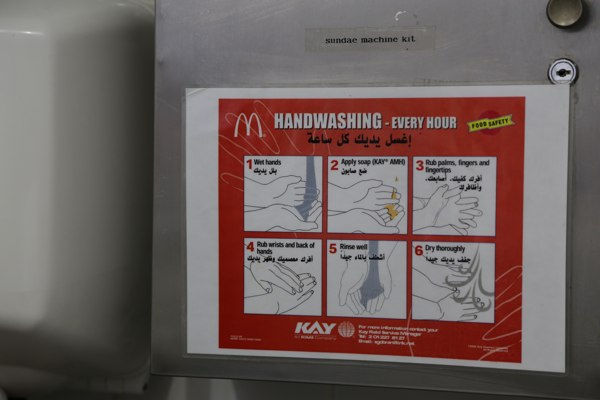

Before anyone is allowed into the kitchen a special cleaning process is required at McDonald's, using a special hand-wash. AMH is the "Anti Microbic Hand-Wash" where every employee is obliged to scrub their hands up to their elbows to guarantee a maximum level of cleanliness. The little details that amazed me back in the kitchen:

- I always complain about Lebanese burgers' thick tomato slices. At McDonald's they have a tomato slicing unit that guarantees the same thickness for all vegetables in all burgers

- All the oils and liquids are filtered in their "Grease Trap Box" to prevent polluting the government’s sewage system

- I didn't see any microwave back in the kitchen. Be sure nothing is reheated and sold again

- The ice cubes are transparent and have a special international standard size

- Four different freezers contain the day's needs: Chicken, fish, meat and fries that are individually placed in separate freezers and are never mixed

- Frying oil is filtered and cleaned every morning

- Magnesol is used to filter oils from any unneeded unhealthy particles

MAGNESOL XL has been marketed to the food industry for more than 20 years and is the leading oil filtration product for restaurant and industrial use worldwide. It is recognized as safe for use as an oil filtration compound by regulatory agencies in the United States, the European Union, Australia/New Zealand, Canada, and over fifty other counties around the world. There have been no verified safety or health issues associated with the use of MAGNESOL XL as a filtration aid.

An international guaranteed quality:

- After cooking, meat stays on shelf for 15 minutes and is directly thrown away afterwards

- No burger is previously prepared. It is prepared on the spot upon order

- All the vegetables on the working table are changed and renewed every two hours

- All the staff change their gloves every hour

- The bread stays outside the fridge for a maximum of 48 hours, after that all will be thrown away

- Frying oil is renewed every 2-3 days

Preparing a burger is an art:

- The bread is toasted for 17 seconds

- The burger should be prepared, filled with its sauces and vegetables in 10 seconds

- The sauces are dispensed in guns, each filling the exact quantity every time

- Ketchup is also dispensed in a special funnel

- While the burger moves on the heated working surface, it maintains its temperature

- The meat is then added. This meat is prepared in a special two-sided grill. A couple of minutes and its out, no need for turning or pressing. A premiere for me.

- The burger is wrapped in its special paper and filled into the carton box ready to be devoured

Preparing the French fries at McDonald’s:

- Fries decent into the frying pan immediately from the Fires Dispenser so they are cooked at freezing temperature. Immediately from -18 to frying, making them absorb less oil

- No defrosting is allowed, even for couple of minutes

- Frying is completed in minutes

- Followed by some shaking to empty the unneeded oil

- 10 seconds of waiting for the oil to drain

- Emptying in the serving container

- 4 grams of salt added

- Client serving in their renowned red box

On the working platforms:

- Vegetables are thrown away and changed every two hours

- Gloves are changed every hour

- A new sanitized towel is changed every hour

- Grilling the meat with blue gloves (blue is not a food color)

- Every spatula, with disposable blades, is made especially for a burger depending on its size

- All unsold cooked meat will be thrown away after 15 minutes

- A burger should be ready in less than 2 minutes

I learned today:

Always add ice to your draft soft drinks as it helps activate the carbonation and taste. Draft soft drinks are created on the spot and need a couple of minutes for the ingredients to react together. Even though some of you like it without ice, ask for a single cube and notice the big difference.

What you see behind the counter:

- McDonald's new policy is "Baked for You". No burger is previously prepared. You ask for it as you like it with any ingredient changed and they are ready to serve it

- Previously, sandwiches used to be stacked for 10 minutes maximum. This rule changed. MFY (Made For You) makes the burger more personalized.

- The new policy of "No Salt is Added" makes your meals healthier. No salt is added to sauces or burgers and the quantity used for every batch of French fries preparation is 4grams instead of 5grams a couple of years ago. (I used to know that salting used to be made by following the letter M, but this has been stopped)

- Every delivery order is served in 3 minutes and 30 seconds maximum.

- Each delivery order is prepared by two persons to go quicker

- The delivery presenter has a table with three different sections: (2) preparing the burgers, (1) adds the soft drinks, (ready) add a straw and deliver to the car

- The ice cream machines pasteurizes the milk every night from 2am until 8am, removing risks of infection

- The same machine is disassembled every 14 days and thoroughly cleaned before a new cycle restarts

McDonald's in Numbers:

- 2 days: Is the lifetime of bread

- 2 hours: Is the lifetime of vegetables on the working tables

- 15 minutes: is the maximum lifetime of a cooked meat

- 3 days: Is the maximum lifetime of frying oil

- 14 days: Cleaning cycle of the ice cream machine

- 1 hour: Timing to change the gloves and to clean all working surfaces

- 210 seconds: Is the drive-through maximum waiting time for the order to be delivered

What I have pointed out before were all taken into consideration and fixed:

- Train more the staff on being welcoming and smiling: A clear improvement

- The drive through staff should be happier, welcoming and more responsive: I clearly felt it. I have never heard anyone tell me ‘Ahla w Sahla’ so many times since they opened years ago.

- Faster service: 3 minutes and 30 seconds is the maximum waiting time

- Wet wipes! Have you ever heard about them having wet wipes in Lebanon? Now they do.

- Every time I paid for a large order of drinks, I always got a cup half full. Today, my cups are filled up to the very top. Finally!

- The French fries boxes always looked empty: Today the boxes are generously filled

- The McFlurry is finally properly stirred and generously filled

- Integrate new items into the menu: The Mexican Burger is the start of a long special limited edition items from around the world

I never imagined it to be this professional. For me, McDonald's is a fast food chain that serves burgers to the mass, and it stops here. I always wondered how they are able to serve the same quality and taste internationally in thousands of restaurants worldwide. Since its not very healthy to have burger and fries daily, we all have that craving that needs to be satisfied occasionally. After this review, you will know better about what you are eating at McDonald’s and that it's clean, prepared with the highest levels of professionalism.